Did you know that over 300 million tons of packaging waste is generated globally each year—much of it ending up in landfills and oceans? As concerns over environmental impact and waste management escalate, extended producer responsibility (Epr) is stepping onto center stage. This article breaks down how EPR laws and stewardship are reshaping global policy, holding producers responsible, and driving the shift toward a circular economy. Whether you’re a policymaker, business owner, or eco-conscious consumer, understanding EPR is essential to taking meaningful action now.

A New Era: Extended Producer Responsibility (EPR) in the Spotlight

“Each year, millions of tons of packaging waste enter our landfills. Extended producer responsibility (EPR) reform promises to change how we view our environmental obligations.”

Unpacking the Urgency: The Environmental Cost of Inaction

The challenges of mounting packaging waste and plastic pollution cannot be overstated. Without effective epr law and unified producer responsibility, mountains of non-biodegradable waste continue to choke landfills, contaminate water sources, and impact public health. In the United States, less than 10% of plastics are recycled, pointing to clear gaps in existing stewardship models and recycling programs. The traditional take-make-dispose approach is unsustainable and directly undermines collective environmental goals and the transition toward a circular economy.

The environmental impact goes beyond visible litter. Microplastics infiltrate food chains, and hazardous chemicals leach into soil and groundwater, ultimately damaging entire ecosystems. A lack of comprehensive epr laws and inconsistent waste management policies among states widen global disparities. This urgent scenario demands that packaging producers, policymakers, and the public rally behind robust extended producer responsibility (EPR) programs to secure healthier, cleaner futures.

What You'll Learn About Extended Producer Responsibility (EPR)

- The fundamentals of EPR law and epr laws

- How producer responsibility and stewardship are shaping new policies

- The importance of EPR for packaging and combating plastic pollution

- Challenges and opportunities for extended producer responsibility in the United States

- Examples and implications of epr programs worldwide

Understanding Extended Producer Responsibility (EPR): An Opinion Perspective

Defining Extended Producer Responsibility (EPR)

Extended producer responsibility (EPR) is a policy approach placing primary responsibility for the entire lifecycle of a product—including take-back, recycling, and disposal—on producers rather than municipalities or consumers. EPR laws challenge corporations to rethink product design, supply chain operations, and stewardship practices, ensuring products are both environmentally responsible and easier to recycle. From electronics to consumer packaging, EPR holds producers accountable beyond just manufacturing by integrating product stewardship with financial and operational consequences.

What makes EPR truly transformative is its potential to create systemic change: when producers are required to pay for or manage waste collection and recycling, it incentivizes more sustainable product life cycles. EPR laws thus create a bridge between policy and tangible environmental impact, positioning producers as critical agents in the journey toward sustainable waste management and a circular economy.

How EPR Laws Drive Producer Responsibility and Product Stewardship

EPR laws fundamentally shift the burden of waste management upstream. Instead of solely relying on local government or consumers, producers become directly responsible for the collection and recycling of their products. This approach not only funds and enhances recycling programs but also encourages more sustainable packaging and product innovation across the supply chain.

Producer responsibility enforced by EPR policy supports effective waste management and environmental protection. By embedding stewardship into legislation, it moves beyond voluntary actions, creating binding obligations. EPR frameworks, such as those adopted in the European Union and parts of the United States, have improved recycling rate metrics, minimized toxic waste, and encouraged greener consumer products—directly aligning economic incentives with public good.

As EPR laws gain traction, real-world implementation can face significant hurdles, including legal challenges that test the resilience of these policies. For instance, Oregon's pioneering EPR program has recently encountered a high-profile lawsuit, highlighting the complexities and potential roadblocks in advancing sustainability efforts. To better understand how such legal disputes can influence the future of EPR in the United States, explore the details of Oregon’s groundbreaking EPR program and its current legal challenge.

The Role of Producer Responsibility Organizations in EPR Programs

A cornerstone of any effective EPR program is the producer responsibility organization (PRO). These stewardship organizations are entities established by producers (sometimes mandated by law) to manage the logistics, reporting, and financing of collection and recycling initiatives. PROs ensure efficiency, transparency, and scale in implementation—especially for complex supply chains and multiple producers.

By aggregating the efforts of many producers, responsibility organizations can negotiate better collection contracts, invest in recycling infrastructure, and raise consumer awareness on proper product disposal. Well-coordinated EPR programs, managed through PROs, overcome the fragmentation often seen in voluntary or local government-run efforts, ensuring a systemic approach to reducing packaging waste and achieving legislative objectives for environmental impact and stewardship.

Is EPR Service Necessary?

Evaluating Whether Extended Producer Responsibility (EPR) Service Is Essential

Is EPR service truly necessary, or is it simply another regulatory burden? The answer lies in the scale of today’s environmental challenges. Traditional recycling programs have not closed the loop on product waste—particularly with complex or hard-to-recycle materials. An EPR service squarely addresses the gaps by holding producers responsible for their products from design to disposal, pushing for higher recycling rates and reduced landfill impact.

Moreover, EPR services do more than facilitate waste collection; they drive upstream change, influencing product design and packaging materials from the outset. As global supply chains and consumer habits continue to evolve, only EPR can create a cohesive framework that aligns private sector innovation with public sector goals. For the United States and other nations aiming for meaningful progress, adopting EPR is both a practical and ethical imperative, essential for the future of waste management.

What is EPR Extended Process Responsibility?

Breaking Down the EPR Extended Process

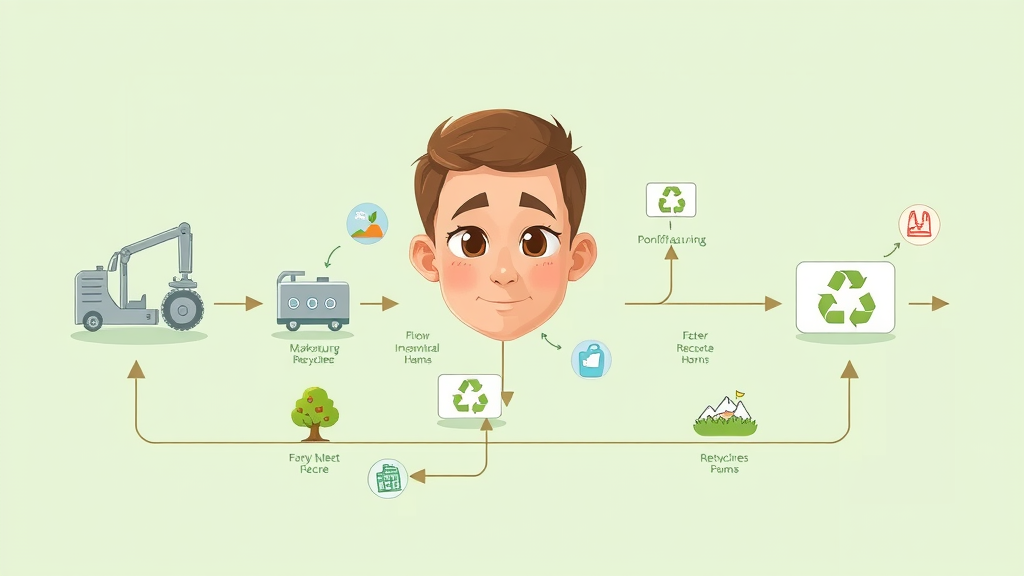

The EPR extended process is an end-to-end solution requiring producers to manage product responsibility far beyond the sale. It involves product lifecycle oversight from manufacturing, distribution, and energy-efficient design to collection, recycling, and even safe disposal. This multi-stage approach ensures stewardship doesn’t stop at consumer purchase but continues until resources are recovered or safely reintegrated into the economy.

At each stage, producers—often through their producer responsibility organizations—assess environmental impact, refine product design, and optimize supply chain logistics to maximize recycling rates. The EPR extended process closes the loop by making producers active agents rather than passive suppliers, ensuring the responsibility program yields measurable environmental benefits, reduces waste management burdens on municipalities, and fosters long-term resource efficiency.

What is EPR and Why Is It Important?

The Rising Significance of Extended Producer Responsibility (EPR)

Extended producer responsibility (EPR) is no longer a niche environmental policy—it’s a global imperative. As the volume of packaging waste and plastic pollution balloons, EPR laws prompt systemic change, requiring all producers—large and small—to rethink their waste management strategies. When executed effectively, EPR does more than increase recycling rates; it fosters environmental stewardship across industries, encouraging innovation in product design and incentivizing circular supply chain practices.

The importance of EPR is underscored by growing international consensus. In the European Union, mandatory EPR programs have successfully reduced packaging waste and boosted recycling efficiency. Across the United States, more states are adopting EPR law frameworks, recognizing that collective producer responsibility is vital for combating widespread plastic pollution, minimizing landfill dependence, and supporting resilient recycling infrastructure. In short, EPR is the missing link between ambitious environmental policy and real-world resource recovery.

What is an Example of Extended Producer Responsibility (EPR)?

Real-World EPR Programs and Their Impact

Consider the Canadian province of British Columbia, one of the world’s most comprehensive EPR systems. Through its epr program for packaging and printed paper, producers are fully responsible for collection and recycling costs—resulting in an impressive recycling rate upwards of 75%. In the European Union, the Packaging and Packaging Waste Directive requires producers to finance end-of-life management, which has spurred systemic changes in packaging design and materials selection, thus lowering environmental impact.

In the United States, states like Maine and Oregon are pioneering new epr laws for packaging, making producers accountable for managing packaging waste and funding stewardship organizations. These real-world initiatives prove that a well-structured EPR program not only cuts landfill waste but also signals to global markets that environmental policy and business innovation can move in tandem, driving long-term sustainability in product stewardship.

| Country/State | EPR Law Name | Focus Area | Year Enacted | Primary Outcome |

|---|---|---|---|---|

| European Union | Packaging and Packaging Waste Directive | Packaging waste | 1994 | Increased recycling rates, eco-design incentives |

| British Columbia, Canada | Recycling Regulation (Product Stewardship) | Packaging & printed paper | 2014 | 75% recycling rate, comprehensive producer funding |

| Maine, United States | EPR for Packaging Law | Consumer packaging | 2021 | Producer-funded waste management, recycling incentives |

| Japan | Container and Packaging Recycling Law | Containers & packaging | 1995 | High collection & recycling rates, reduced landfill burden |

The Case for EPR Laws: Why Producer Responsibility Matters Now

Opinion: Without EPR, Producer Responsibility Remains Incomplete

In my view, any attempt to address plastic pollution and packaging waste without robust EPR laws is fundamentally incomplete. Voluntary action may inspire positive headlines, but only binding legislation ensures that all producers play their part. EPR policies move us from fragmented stewardship to comprehensive, inclusive action—raising the baseline for what responsible product stewardship looks like worldwide.

By implementing producer responsibility programs within strict legal frameworks, nations and states can move past incremental improvements and engage in true policy leadership. Universal adoption of EPR would redefine environmental policy not just as compliance, but as an ongoing commitment woven into the fabric of business and government decision-making. The responsibility program embedded in EPR is what bridges the gap between intention and action, delivering transparent, measurable results for the planet and future generations.

How EPR Laws Reshape the United States Approach to Waste

The United States is at a pivotal point for redefining its waste management strategy. While many cities and states have long relied on local government-driven recycling programs, recent momentum reveals a new direction: state-level EPR laws shifting the onus to manufacturers. In states like Maine and Oregon, industry-funded models not only relieve budgetary stress on municipalities but also ignite innovation among producers to minimize waste upstream.

National EPR adoption would create clearer, more consistent rules for packaging waste while improving coordination with producer responsibility organizations. As producers become more involved in circular economy initiatives, more sustainable materials and design approaches are brought forefront, positively affecting product stewardship nationwide. In this way, EPR shapes an integrated response that makes producers responsible for environmental impact, aligning business incentives with public benefit.

“Extended producer responsibility is not just policy; it’s a paradigm shift towards collective accountability.”

How EPR for Packaging Combats Plastic Pollution

- Drives innovation in recyclable packaging

- Reduces single-use plastics

- Promotes collaboration with producer responsibility organizations

As plastic pollution reaches crisis levels worldwide, epr for packaging emerges as a foundational tool for change. By mandating that packaging producers design for recyclability and invest in responsible management, EPR policy actively reduces reliance on single-use plastics. The innovation driven by these requirements—from edible packaging solutions to advanced material recovery—breaks the cycle of disposable waste.

Furthermore, the collaboration fostered by producer responsibility organizations amplifies the effectiveness of EPR programs. When all stakeholders—from material suppliers to retailers—work together, the result is more efficient, scalable solutions that reduce contamination, minimize environmental impact, and support a vibrant recycling market. This integrated policy approach is essential not just for mitigating packaging waste today, but for building a sustainable, plastic-free future.

Critiques and Challenges: Implementing Extended Producer Responsibility (EPR)

Obstacles in Enforcing EPR Laws

Despite its promise, EPR faces real-world enforcement challenges. Varied local government capacity, inconsistent legislative frameworks, and industry resistance all slow the adoption of effective EPR measures. Some producers responsible for legacy waste streams lack technical knowledge or infrastructure, making compliance difficult. Additionally, fragmented data tracking and complex supply chains can lead to inefficiencies and loopholes within even the most well-designed epr law.

Education and stakeholder buy-in remain persistent hurdles. Without broad public awareness and robust oversight, EPR risks being perceived as a bureaucratic mandate rather than a vital stewardship tool. Overcoming these obstacles requires not just stronger policy, but also cooperation among producers, regulators, and consumers to build a culture of shared responsibility for environmental impact.

Balancing Costs: The Burden on Producers and Consumers

One challenge of EPR programs is the associated cost. While producer-funded waste management relieves strain on municipalities, it can raise expenses for manufacturers—costs that may be partially passed to consumers. Some critics argue this could reduce affordability or stifle innovation, especially for smaller producers.

However, the long-term economic and environmental benefits often outweigh short-term expense. EPR programs create market incentives for eco-friendly product design, streamline collection and recycling, and can ultimately lower waste disposal costs system-wide. Smart policy design and phased implementation help ensure a balanced distribution of costs and benefits as industries and supply chains adapt.

Global Disparities: Progress of EPR Programs in Different Markets

Internationally, the pace of EPR adoption varies sharply. The European Union has pioneered many successful EPR frameworks, achieving high recovery rates and fostering a robust circular economy. In contrast, the United States offers a patchwork of state initiatives, resulting in uneven outcomes and slower progress at the national level.

Developing markets often lack the legislative infrastructure or technical resources to roll out comprehensive EPR programs. Closing this global gap will require investment, knowledge sharing, and tailored policy approaches to ensure that EPR remains equitable and effective across all economic contexts. Only by scaling stewardship across borders can EPR meet its potential as a unifying force for environmental protection worldwide.

Key Takeaways: The Urgency of Extended Producer Responsibility (EPR)

- EPR laws are crucial for systemic change in waste management

- Producer responsibility must extend beyond compliance

- Product stewardship should be integrated into business models

Frequently Asked Questions About Extended Producer Responsibility (EPR)

-

What products are most commonly covered by EPR laws?

EPR laws most commonly target electronics, batteries, packaging, tires, and certain consumer products that are challenging to recycle. These items often have significant environmental impact or pose disposal challenges, making them key priorities for responsibility programs and stewardship organizations. -

How does EPR differ from traditional recycling?

Unlike traditional recycling, where the cost and responsibility are usually managed by local government, EPR shifts accountability to producers. This model funds and optimizes the entire process—from design through collection and recycling—ensuring consistent quality and higher recovery rates for targeted product categories. -

Can EPR programs be voluntary?

While some EPR initiatives are voluntary, especially in their early stages, most impactful programs are mandatory. Mandatory epr laws ensure all relevant producers participate, preventing "free-riding" and guaranteeing comprehensive stewardship across supply chains. -

What are the penalties for non-compliance with EPR regulations?

Penalties for non-compliance vary but can include financial fines, restrictions on product sales, and court-mandated corrective actions. These enforcement measures ensure that producers and stewardship organizations uphold their responsibilities within the regulatory framework.

Conclusion: The Future of Extended Producer Responsibility (EPR)

Opinion: Will EPR Become the Global Standard?

A global standard for extended producer responsibility (EPR) is not only plausible but necessary as waste, environmental impact, and plastic pollution transcend borders. With more governments and companies embracing stewardship, the transition to normalized EPR laws seems inevitable—provided that policy remains adaptive, enforceable, and inclusive.

Your Role in Supporting Extended Producer Responsibility

Consumers, producers, and policymakers each have a stake in the sustainability journey. By demanding smarter waste solutions, supporting EPR-friendly brands, and advocating for strong legislation, everyone can help amplify the reach and effectiveness of extended producer responsibility (EPR).

Take Action: Demand Smarter Waste Solutions with Extended Producer Responsibility (EPR)

It’s time to move from conversation to action. Support extended producer responsibility (EPR) in your community. Choose responsible brands, participate in stewardship programs, and advocate for legislation that holds all producers responsible for their products’ lifecycle. A cleaner, healthier tomorrow starts with the choices we make today.

As you continue to explore the evolving landscape of EPR and sustainable waste management, it’s important to recognize how broader market forces can influence the effectiveness of these programs. Shifts in recycled commodity pricing, for example, have a direct impact on the financial stability of waste haulers and the overall recycling ecosystem. For a deeper look at how these economic trends are shaping the future of recycling and producer responsibility, discover the latest insights on the effects of declining recycled commodity prices on waste hauler earnings. Understanding these dynamics will empower you to make more informed decisions and advocate for resilient, forward-thinking sustainability solutions.

Extended Producer Responsibility (EPR) is a policy approach that holds producers accountable for the entire lifecycle of their products, including take-back, recycling, and disposal. This strategy incentivizes manufacturers to design environmentally friendly products by internalizing the costs associated with waste management.

For a comprehensive understanding of EPR, the Wikipedia article titled “Extended producer responsibility” provides an in-depth overview of its origins, implementation, and global examples. This resource delves into how EPR policies have been adopted worldwide and their impact on waste management practices.

Additionally, the article “Extended Producer Responsibility (EPR) | WRAP - The Waste and Resources Action Programme” offers insights into the significance of EPR in addressing global waste challenges. It highlights the role of EPR in promoting sustainable product design and reducing environmental impacts.

If you’re serious about understanding and implementing EPR strategies, these resources will provide you with valuable insights and practical guidance.

Add Row

Add Row  Add

Add

Write A Comment